Tuning

There is two main ways of ignition tuning: dyno cell-based / run and road-based tuning.For road-based tuning, two people is essential. One driver receiving instructions for driving style and another on the laptop performing adjustments. It is impossible to do both tasks with only one person.

David is not liable for mistakes or the result of the user. We aim to provide ideas on what to adjust and where to adjust table figures. If you do not know what you are doing, it is best to go to a dyno tuner and let him do the job for you, since he has the experience and knowledge (although some will argue that several tuners do not perform an ideal job... hence the willingness to get involved to make minor adjustments)

NOTE: Software screenshots shown here is not part of Knock Defender.

Road-based Tuning

It takes a bit of skill and practice to get the hang of road-based tuning. You could be tuning for boost-ramp (2500-3500 RPM) only, or for maximum torque (3500-6000 RPM), or both.The most important is measuring before-and-after ignition table changes. If the changes do not make sense (in that the result does not match up with your expected assumption), then stop and have a think about as to why before either reverting changes or proceeding with further changes.

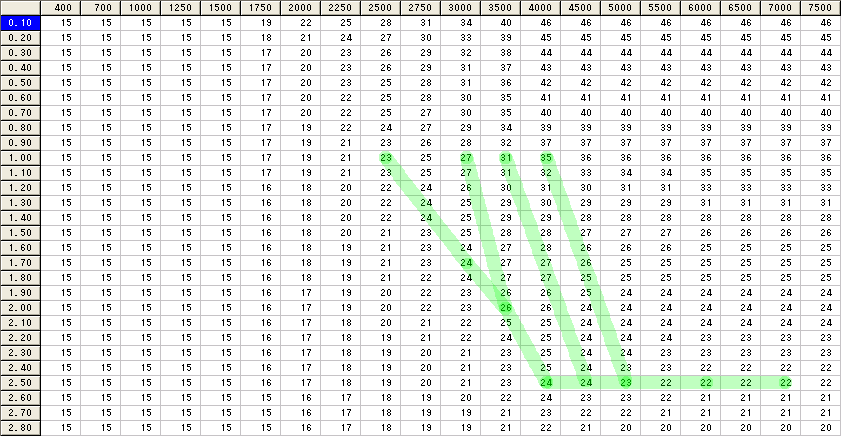

Nissan Skyline RB25DET: AFM: stock engine: 7 psi boost

Airflow-RPM ignition table is quite a bit different to MAP-RPM ignition table. It is given here as an example, and proof that it can be done.

The green path shows typical trace path of ignition, based on airflow rate and RPM. It is best to log or trace path ignition before performing any sort of changes.

Ignition should be altered in clusters of 2x2 or 3x3 cells. For sub-3500 RPM ignition tuning, it is best to use 3rd or 4th gear and at maximum boost (or airflow rate), and adjust on-the-fly until knock is triggered and back-off 1 or 2 degrees.

Logging airflow rate, rpm, ignition and knock level is the best and most precise approach. If a knock level of >60 is logged, the exact cell should be adjusted, then surrounding cells be interpolated both horizontally and vertically. Alternatively 3x3 cell should be adjusted together.

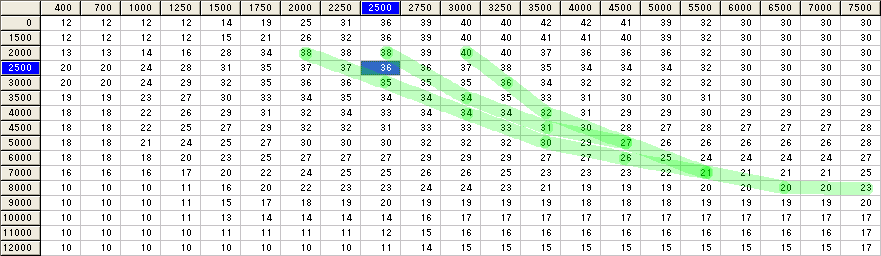

Toyota 1JZ-GTE: MAP: 14 psi boost

The 1JZ-GTE ignition table is suited for 14 psi boost maximum application, and it is an example prior to changes made predominantly in the sub-3500 RPM region. I can personally say that this region (2000-3500 RPM) is the most important.

For sub-3500 RPM ignition adjustment, it can be done vertically in several groups:

• 0.3 kPa to 1.0 kPa (abs)

• 1.0 kPa to 1.5 kPa (abs)

• 1.5 kPa to 1.8 kPa (abs)

For 3500+ RPM ignition adjustment, it can also be done vertically but is less critical. The most important is at near-to-full boost (1.8 to 2.1 kPa abs) from 3000 RPM to 5000 RPM (maximum torque) then to 7000 RPM. At maximum torque and the same boost level, ignition should be minimum.

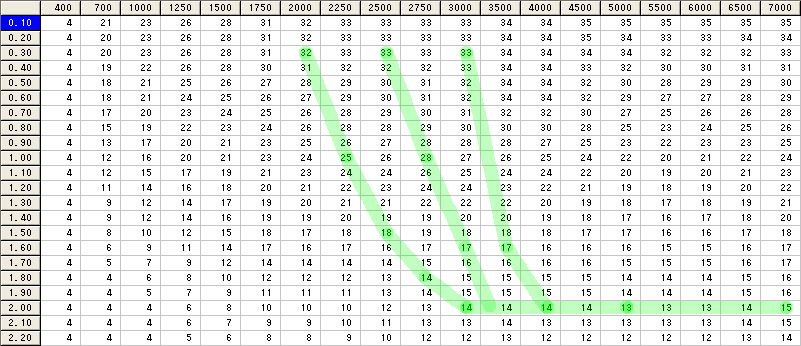

Toyota 2JZ-GTE: MAP: 22 psi boost and 1000cc injectors